You are here:

HomeProductstetra n butyl titanate (TnPT/TnBT)

tetra n butyl titanate (TnPT/TnBT)

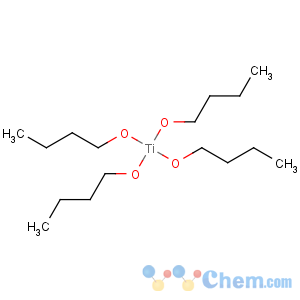

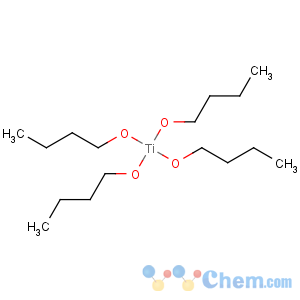

-

Molecular Structure

Detailed Description

FD-TnPT can be used directly or indirectly as

a catalyst or catalyst additive, as a coating primer or

added to a formulation as a adhesion promoter and as

the base material in the formation of sol-gel systems

or nanoparticle systems or products. Some typical

applications for FD-TnPT are:

Catalyst:

As esterification catalyst FD-TnPT is used in

an amount of ca 0.01-1 %. The titanate is often added

as the last ingredient of the reaction components to

prevent undesired pre-reactions. Transesterifications

run at low temperatures < 100 degree. Esterifications

(e.g. plasticizer preparation) need temperatures of >

180 degree. For Ziegler-Natta catalysis FD-TnPT

is mainly used in combination with Al compounds.

Crosslinking:

For cross-linking reactions FD-TnPT is added

to the polymer / binder in concentrations of ca. 0.5 -

5 %. The reactivity of FD-TnPT is very high;

depending on the polymer sometimes other less

reactive FD-TnPT products have to be used.

Coating:

Titanium dioxide layers can be prepared by thermal

or hydrolytic degradation of FD-TnPT.

Thermal decomposition occurs at > 350 - 600 degree.

FD-TnPT is preferably applied by vapor

deposition in a stream of a dry gas or by spraying

forming on a hot substrate a thin layer of titanium

dioxide. By spraying, dipping or brushing of the

substrate from solutions and subsequent hydrolysis

by moisture also TiO2 layers are formed.

Primer:

As primer FD-TnPT is applied normally in

very low concentrations of ca. 0.1-5 % in an organic

solvent. Heating after appliance to ca. 80-100 degree for

a short time might be of advantage.

Gel:

Total or partial hydrolysis of FD-TnPT

preferably in the presence of chelating agents or in

combination with other metal alkoxides affords via a

sol-gel step metal oxides for use as binder or coating.

- tetra n butyl titanate (TnPT/TnBT)

steel_wong@hotmail.com

steel_wong@hotmail.com