You are here:

HomeProductsefficient environmental protection vulcanizing agent,rubber auxiliary, DMTD dimercaptothiodiazole vulcanizing, CPE chlorinated polyethylene crosslinki

efficient environmental protection vulcanizing agent,rubber auxiliary, DMTD dimercaptothiodiazole vulcanizing, CPE chlorinated polyethylene crosslinki

-

- Product Nameefficient environmental protection vulcanizing agent,rubber auxiliary, DMTD dimercaptothiodiazole vulcanizing, CPE chlorinated polyethylene crosslinki

- CAS No.51988-14-8

- Purity99.5% mix

- Min Quantity15Metric Tons

- Price20500~21000

View Contact Detail

View Contact Detail

-

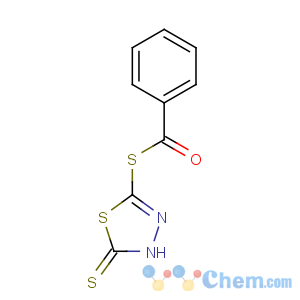

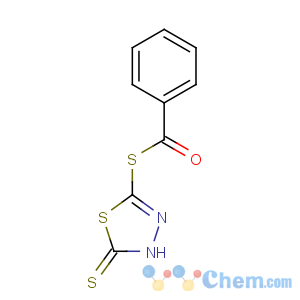

Molecular Structure

Detailed Description

Name ACTOR-TDDS(the same as ECH.../TDD)

CAS NO. 51988-14-8

specification "A vulcanizing agent is designed for use with halogenated elastomers such as chlorinated

polyethylene (CPE). It is supplied as an off-white powder with a specific gravity of 1.46. ACTOR-TDDS is a

blend of esters of 2,5-dimercapto-1,3,4-thiadiazole.

In general, CPE compounds exhibit good resistance to oil, heat, and ozone. The appropriate choice of

vulcanization system and formulating ingredients is the key to the ultimate performance and cost

effectiveness of CPE compounds. Peroxides have commonly been used as the cross-linker for CPE in

applications requiring optimum compression set and heat resistance. For less stringent applications, the

use of ACTOR-TDDS allows for a more highly-extended, lower-cost compound than is possible with peroxides.

The resultant vulcanizates cured with ACTOR-TDDS are high-performance compounds with heat resistance only

slightly less than that obtained by peroxide cures.

advantages - Single pass mixing.

- No bloom or surface stains.

- Cure rate that can be accelerated.

- Cures not inhibited by oxygen.

- Lead-free compounds.

- Low compound cost."

function "ACTOR-TDDS functions as a di-nucleophile, vulcanizing any elastomer containing replaceable halogen atoms.

Because of this, many inexpensive fillers, oils, and plasticizers can be used with ACTOR-TDDS. The cure

mechanism of ACTOR-TDDS involves hydrolysis of the thioester bonds within ACTOR-TDDS to form a

dimercaptide intermediate. This di-nucleophilic species then displaces halogens on the elastomer

backbone to become a cross-link.

ACTOR-TDDS should be used in conjunction with an amine accelerator and a basic metal oxide acid

acceptor/cure activator. "The cure rate can be increased by increasing the level of the amine accelerator or

of the metal oxide; however, this often results in reduced heat-aging performance.

- efficient environmental protection vulcanizing agent,rubber auxiliary, DMTD dimercaptothiodiazole vulcanizing, CPE chlorinated polyethylene crosslinki