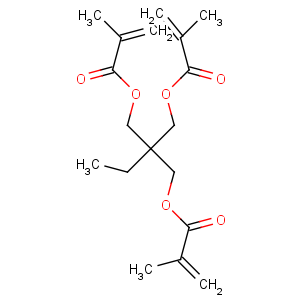

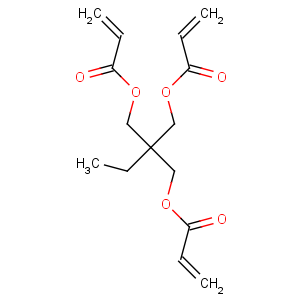

Trimethylolpropane trimethacrylate

CAS No. 3290-92-4

EINECS No. 221-950-4

MF C18H26O6

Quality standard

Purity min. 95%

Acid content max.0.3% (acid-base titr., calculated as MAAC)

Watercontent max.0.2%

Color max.50 (Pt-Co)

Stabilization 150±10 ppm MEHQ (HPLC)

physical data

Appearance clear, colorless liquid.

Odor ester-like

Molecular weight 338.4 g/mol

Density 1.060 g/cm3 (20℃)

Refractive index n20/D 1.74(lit.)

Boiling point +200℃

Melting point -25 °C

Vapor density >1 (vs air)

Vapor pressure <0.01 mm Hg ( 20 °C)

Flash point >230 °F

Principal Use

1. Trimethylolpropane trimethacrylate could Improve the properties of ani-corrosion, anti-age and increase the rubber hardness, thermal resistance, absorb the per-oxide product’s(like DCP) smell when in the process of vulcanizing.Help the rubber more plastic when in the mix process,make the vulcanized rubber more harder. Suitable for MBR, EPDM, ACM and CR ,etc.

2. Crosslink agent,rubber modifier TMPTMA could decrease the radiation dosage, save the radiation time,increase

the crosslink density,low viscosity,high crosslik properties,low vapo tensionhigh speed solidity

3.curable printing ink of UV 、EB or heating,coating, adhesive

Packaging

Plastic drums or stainless steel tank,200kg net weight.

Transportation and Storage

Avoid shine, rain and high temperature in transportation;Store the products in cool, shady and ventilated conditions, keep far away from fire;12 months from date of delivery at a maximum storage temperature of 30℃.

Permanent link: http://www.vvchem.com/sell/cas:3290-92-4,3322653.html