Title: Polyvinyl Alcohol

CAS Registry Number: 9002-89-5

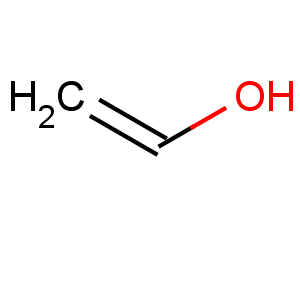

CAS Name: Ethenol homopolymer

Synonyms: PVA

Trademarks: Akwa Tears (Akorn); Elvanol (DuPont); Gelvatol (Monsanto); Liquifilm (Allergan); Mowiol (Hoechst); Polyviol (Wacker); Sno Tears (Chauvin); Vinarol (Gen. Dyes); Vinol (Air Prods. Chem.)

Literature References: A polymer prepd from polyvinyl acetates by replacement of the acetate groups with hydroxyl groups. The alcoholysis proceeds most rapidly in a methanol + methyl acetate mixture in the presence of catalytic amounts of alkali or mineral acids: Hermann, Haehnel,

Ber. 60, 1658 (1927).

Monograph: C. E. Schildknecht,

Vinyl and Related Polymers (Wiley, New York, 1952). The head-to-tail or 1,3-glycol structure is favored: Staudinger

et al., Ber. 60, 1782 (1927);

J. Prakt. Chem. 155, 261 (1940); Marvel, Denoon,

J. Am. Chem. Soc. 60, 1045 (1938); McDowell, Kenyon,

ibid. 62, 415 (1940); Marvel, Inskeep,

ibid. 65, 1710 (1943).

Reviews: M. Leeds in

Kirk-Othmer Encyclopedia of Chemical Technology vol. 21 (Wiley-Interscience, New York, 2nd ed., 1970) pp 353-368;

Polyvinyl Alcohol, A. C. Finch, Ed. (Wiley, New York, 1973) 640 pp; A. S. Dunn,

Chem. Ind. (London) 1980, 801-806. Vinyl alcohol monomer has not been isolated.

Review: R. B. Seymour, G. B. Kauffman,

J. Chem. Educ. 71, 582 (1994). Comprehensive description: D. Wong, J. Parasrampuria,

Anal. Profiles Drug Subs. Excip. 24, 397-441 (1996).

Properties: Dry, unplasticized polyvinyl alcohol powders are white to cream colored, soften at about 200° with decompn. Commercial polyvinyl alcohols have different contents of residual acetyl groups and therefore different viscosity characteristics. The first code number following the trade name indicates the degree of hydrolysis, while the second set of numbers indicates the approx viscosity in cP (4% aq soln at 20°). Polyvinyl alcohols are essentially sol in hot and cold water, but those coded 20-105 require alcohol-water mixtures. Aq solns are colloidal and compatible with lower alcohols. Pure aq solns are neutral or faintly acid and subject to mold growth. Insol in petroleum solvents.

Use: In the plastics industry in molding compds, surface coatings, films resistant to gasoline, textile sizes and finishing compositions; can be compounded to yield elastomers to be used in manuf artificial sponges, fuel hoses, etc., also in printing inks for plastics and glass, in pharmaceutical finishing, cosmetics, water-sol film and sheeting. Pharmaceutic aid (viscosity increasing agent); ophthalmic lubricant.